How does a turbocharger work?

First let’s look at what makes up a turbocharger:

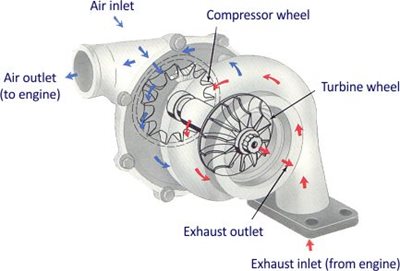

A turbocharger consist of two sections: the turbine and compressor. The turbine can further be broken down into two components the turbine housing and the turbine wheel. The turbine housing funnels the exhaust gases produced by the engine into the turbine wheel, the pressure from these exhaust gases then rotates the turbine wheel. The gas then continues to flow and exit out of the exhaust outlet.

Image 1: Diagram of a turbocharger that shows flow of gases

(Source: Schwitzer Turbochargers)

Like the turbine, the compressor is also broken down into two components, the compressor wheel, and the compressor housing. The compressor wheel is attached to the turbine wheel via a steel shaft so as the exhaust gases rotate the turbine wheel the compressor wheel also rotates. As the name suggests, this rotation of the compressor wheel sucks in air and compresses it. The compressed air is then forced into the engine enrichening the air fuel mixture and giving the engine the ability to burn more fuel and therefore produce more power.

In the simplest terms, all a turbocharger does is add additional compressed air to the engine to improve the efficiency of the combustion process.

Why do diesel engines typically use turbochargers?

As highlighted above, a turbocharger increases an engines efficiency and performance by funnelling extra compressed air into the combustion chamber and creating a more efficient combustion process. Compressed air is denser with oxygen molecules, therefore can help burn fuel faster as oxygen a key component in the combustion process. This allows the potential for a vehicles engine to be smaller in capacity, in turn creating weight savings and improving fuel economy. Therefore, it is common to see a turbo charged diesel vehicle equipped with a smaller capacity engine, than the equivalent petrol engine fitted to a comparable vehicle.

Diesel engines are ideal for turbocharging because they are not as affected by a leaner air fuel ratio as a petrol engine. This is due to the torque control of a diesel engine being controlled by the mass of fuel that is injected into the combustion chamber rather than the quantity of the air fuel mixture like in a petrol engine.

The additional air in the cylinder from the turbocharger helps to increase the compression ratio of a diesel. The compression ratio refers to the ratio between the volume of the cylinder and combustion chamber. Diesel engines do not utilize a spark plug so they need to utilise higher compression ratios to increase the temperature of the air within the cylinder to properly ignite the diesel fuel for the combustion process.

What are the benefits of a turbocharger over a naturally aspirated engine?

- Performance Increases

- Torque Increases

- Improved Fuel Economy

- Improved engine efficiency

- Better towing due to the torque increases

- Better off roading ability due to the torque increases

The vast majority of all modern diesel engines utilize turbochargers for the gains in both engine power and efficiency.

United Fuel Injection have the most experienced turbocharger staff in Western Australia, we can test and diagnose any turbo issues, repair damaged turbos, remanufacture worn turbos and supply new units. We are Garrett Master Distributors and suppliers for all the main turbocharger manufacturers around the world.

Call us today for any of your turbocharger concerns and find out how we can help you.